Introduction to A case of COFCO and Apple in Managing Strategic Resources and Operation Management

All the Companies run their business with the help of their skill, capability, and knowledge of Managing Strategic Resources and Operation Management. All the companies have to compete in a same business environment. There are several factors in a business environment, which influence the business operation (Mura, 2012). The company, which can best utilize its resources, do better and have a competitive advantage in the market. The utilization can be maximised by reducing waste and cost. It can also be done through increasing efficiency and rate of operation (Ebiringa, 2011). There are several tools available for analyzing the performance of the companies. We can know about the strategies taken by the top performing companies by analyzing their performance over the years. For this purpose we can take the reference of Apple and COFCO operates in different countries and are the leaders in electronics, food processing; and metal and mining industries respectively (Ali, 2012).

Apple is an American multinational company, which is an electronics consumer goods maker company, which is known for its technology and innovation. It has its own operating system and own product range of iPods and iPhone, etc (Kaya et al. 2010). It is the world’s third largest mobile maker company and second Information Technology Company. Apart from that, it is the most admired company in America (Koon and Juhary, 2011).

COFCO is china based food processing company. Its unique selling proposition is that it is involved in planting to warehousing and transporting (McCann and Aravamudhan, 2013). Apart from that, it has a diverse business range of hotels and real estate etc. It is the largest food processer and trader of China.

1.1 History and evolution of Apple and COFCO

Apple Company is based on manufacture of mobile phones so it is the most growing industry. Marketing and sales of product is very much necessary because target rates are very much high. Employees are expected to get high salary, as it is multinational concern (Arthur, 2012). Mobile phone market is focused on huge amount of sales and the most important fact is halo effect based on impression and goodwill of basis on Operation Management. As the basis of capturing the cell phone market the in the 2001 apple introduced jukebox was introduced that was 1000 songs in the pocket. In the year 2003 launched music store with iPod which is thinner (Armstrong, 2012). Apple introduced Nike and iPod, including sensor and iPod nano. Customers who are very much addicted to music and tunes, which are melodies, can get a shy of relief if that person is a customer of apple as songs over 300 can be downloaded in few seconds.

Apples I phone are famous all over the world. People who are aware of the fact that apples market right from 2001 was dealing in jukebox that was merely 100 songs but in the year 2010 apples introduced a device, which produced 350 million songs. On the basis production of phones it has produced a lot in 10 years (Bondarouk., 2011).

COFCO Company is based on National cereals, oil, Foodstuffs Corporation and in 2001, it was the sole importer and exporter of oilseeds. As production of oilseeds is based extracting, so it requires huge amount of skilled and expert people (Bratton and Gold, 2010). As undoing, this fact its production has increased from 1500 tonnes to10000 tonnes in the year 2012. This fact is relevant from the data that is has extended its operations in other 60 countries in the world. COFCO Company started its business in the area of food products so it is a way to inculcate the various aspects of job. In case of sales revenue the global revenues sales revenue increased from 398 to 500 (Davis, 2011). In case of COFCO company has shown significant improvement in case broiler firms can be shown in tables as below

| Annual production | 2010 | 2011 | 2012 | %change in 2010, 2011 |

| 1.1-2010 | 35,613036 | 37,876534 | 36,56432 | -2.91 |

| 3000-4500 | 588,233 | 567,456 | 21,23347 | -2.21 |

| 5000-6000 | 655,4567 | 678543 | 24,4567 | 12.65 |

| 7000-8000 | 6547892 | 6888763 | 33,87656 | 10,76 |

Table 1: Annual production COFCO

(Source: Mitchell et al. 2013, p-109)

1.2 Comparison of strategies taken by both Apple and COFCO with global perspective

In case of comparison in case of Apple and COFCO Company, Apple Company is very much a lot of intense and high technology should be used in case of Apple Company. In transfer of goods, Apple Company is much more flexible and supply chain management in case of managers and other logistics management are much more versatile (Dickmann, 2009). Apple Company saves much more time and cost but COFCO Company is very much a time consuming and defensive. COFCO needs much more delivery man and sales executives but on the basis needs and arguments of the company, but apple company much more engineers and financial managers who can just make it technically sound and financially liable (Lamming et al. 2012).

| Apple | COFCO | ||||

| Flexible | Defensive | ||||

| Technologically sound | Technologically backward | ||||

Table 2: Apple and COFCO strategies

(Source: Marcer, 2012, p-16)

ORDER This Operation Management Assignment NOW And Get Instant Discount

This table above shows that on the basis of technologically soundness Apple to compared to COFCO is much more advanced and not of a defensive kinds of nature.

In case of Apple Company, stores were various kinds of technological equipment and parts are stored, it should be airtight and various kinds of machines should be installed to make it technologically sound (Moutinho, 2010). Just in time, concept focuses on strategic management, manufacturing, and operating hi end costs. Total quality management decreases the cost, it increases the efficiency and effectiveness of the employees, and policy of production of works (Mura, 2012). Techniques of employee resistance and work of resistance:

| Heads | Apple | COFCO |

| Employee motivation | 500 | 100 |

| Cost reduction | 600 | 200 |

| Effectiveness | 400 | 100 |

| Culture | 700 | 200 |

| Integration | 200 | 100 |

Table 3: Various techniques of employee resistance

(Source: McCann and Aravamudhan, 2013, p-69)

COFCO is based on various three dimensions and also it can be very much a ongoing process of internal environment and obsolete and facing the competition of various companies as also giving a riding a car without break (Ebiringa, 2011).

Various experienced personnel have been hired from various universities and various countries across the world. At last we can clued that is various kinds of operations based on the marketing of oilseeds is going on in a smooth manner. In case of oil, business and food processing industry the techniques used are of traditional nature (Ali, 2012). Store management is always important as in case of large companies like Apple and COFCO. On the other hand in case of several of manager in case of advantage and disadvantage of various people and jobs Supply chain managers working under the perspective of Apple is of quick and of varied nature also in case of paramedical forces and intensification of persons (Kaya et al. 2010). Apple is fast in case of touch phones, android phones which requires good communication and satellite facilities, it focuses technological variance but COFCO group is always a defensive and mainly relies on justification of transport and airlines industry. Apple needs much more financial help from its business as compared to COFCO (Koon et al. 2011). In case of economic recession or intangible market situation, it will affect the Apple Company if it is an IT recession period.

Food poisoning and virus-affecting animals like ship, hen, and pigs that produce many kinds of products every day can surely affect COFCO companies business. In case of eatables and baby food, the company should select and discuss with nutritionals so that it contains pure and solid so the newborn babies are not affected by poison (McCann and Aravamudhan, 2013). Apple vs. COFCO has been always a two-sided issue, Apple deals with computerised intensification and a diverged value of science and technology. Apple normally hires people from the science background but COFCO Company hires COFCO company is based on various three dimensions and also it can be very much an ongoing process of internal environmental science and obsolete and facing the competition of various companies as also giving a riding a car without break (Mitchell et al. 2013).

Various experienced personnel have been hired from various universities and various countries across the world. At last we can clued that is various kinds of operations based on the marketing of oilseeds is going on in a smooth manner (Norouzi et al. 2013). In case of oil business and food processing industry the techniques used are of traditional nature. Store management is always important as in case of other blue chips and especially in case of several of manager and in case of advantage and disadvantage of various people and jobs (Omolo et al. 2013). Apple hires people from science background but COFCO hires people from commerce background.

Apple concentrates on chemicals for making liquid crystal display, In case of various jobs on the basis IT products the apple company can reduce the unemployed rate more in case of engineers and management people. COFCO industry can reduce the unemployment rate of people of labour and agents who can transfer the food products to go downs and shopping centres (Shahzad, 2008). Apple Company is very much responsible for quick transformation of information from shipping industry to various people and going people. In case of production and sales Apple Company is much more ahead. Giving away the most important part that is sophisticated part various kinds that produce more jobs. In case of hike in salary people working in apple will get and advantage to progress in the field which produces maximum amount of capital so in case of COFCO (www.COFCO.com, 2014).

1.3 Sustainable operations as a result of integration

All manufacturing firms need to some basic steps to run their business. It consists of raw material procuring, distribution channel maintaining and fulfilling of customer demand in time (Parnell, 2013). There are three tiers of sustainability, which the companies like Apple, COFCO do follow. For this, they need to follow the basic things rightly. For this, they need to reduce the amount of wastes. Fuel consumption can be reduced largely by taking optimum route of transportation. A proper planning can do that. To obtain best utilization from the resources apple uses modern technology (Peng et al. 2009). It procures its raw materials electronically. It reduces their inventory and stock risk. The use of green fuel reduces the carbon footprint.

ORDER This Operation Management Assignment NOW And Get Instant Discount

It transact with their dealers and suppliers electronically. It uses software like SAP for this purpose. It helps in planning the chain. Apple then communicates the messages to the subordinates (Shafique, 2013). They train their employees accordingly. If they need to improve the skill, they can do it timely. If they lag in something, they can collaborate with other countries. It follows Six Sigma efficiently, which gives a competitive than its competitors. It clarifies the processes, steps to its employees, which results in getting better outcomes. It helps in total quality management (Altarawmneh and Al-Kilani, 2010).

COFCO is a food chain company. It is very important for its business that it integrate all the components of its business effectively. It uses organic fertilizers that pay back for a long term. It maintains its work force by paying them proper wages. It helps in workers attrition rates by 20% (Andersen and Minbaeva, 2013). It reduces its inventory cost by optimizing the holding food product. It also reduces the product distortion rate by 7.1%. COFCO provides total quality management to its customers, which further results in increasing outcome of the company (Hoffman, 2013).

1.4 Sourcing raw materials

In supply chain management, sourcing is the most important factor cause when a company targeted to start a new segment first priority is the resource whether they are able to deliver it to the customers or not (Shahzad, 2008). COFCO has targeted wide area market as per its requirement but with the purpose of research, it has able to deliver the product. Currently it is holding 80% of share in Chinas per the Forbes, 2009 (Wang et al. 2009).

COFCO is one of the biggest retail companies in the China and worldwide. Company usually deals in food items like gains and now it holds a huge market share of 92% of food supplies within the china. It has achieved it because of its strategy taken several years back. It has diversified its business by merging and acquiring other giant companies (Omolo et al. 2013). Now, it is operating in seven countries. It has been able to do so by improving its strategic efficiency and effectiveness. The process consists of identification, prioritization, and exploiting of the opportunities. It reduces adverse situations.

COFCO on the other hand majorly sourced its required raw materials through its subsidiary companies. The mother company has 10-15 subsidiary companies under their belt through these companies the mother company sources their materials (Hoffman, 2013). There are only a few occasions where the company sources its required materials from the local and international suppliers. The study by Parnell (2013) showed that the company majorly collects and does the agreement through the subsidiary companies because the agreement with the subsidiary companies helps the subsidiary companies to earn a substantial amount of revenue that helps those companies to grow. The subsidiary companies develop the sourcing contracts with the local agencies in most of the cases with the local farmers and the suppliers. The main advantage of the sourcing strategy is that the company developed a knowledge sharing ground that helped them to gain the trust and loyalty from the suppliers. The main issue what has been seen that the both the companies are sourcing their materials from the local suppliers and developed one good relationship with those suppliers which enabled them to get a stable sourcing of the raw materials required for the production line. According to McCann and Aravamudhan (2013), the best thing what this company does is that it does not shares direct liability with the suppliers it diverts this risk with the inclusion of the subsidiary companies. The most positive thing what this company has done is that it took the initiative to enrich the subsidiaries. According to Norouzi et al. (2013), the enrichment of the subsidiary companies will help the suppliers to get more benefits than doing contract with the main company.

Apple follows lean operation technique. It is an integration of technology with the business processes and human. Human means both customer and employees (Zagenczyk et al. 2009). Employee motivation increases the work efficiency. Customer satisfaction increases customer loyalty. Apple uses various supply chain management for meet the requirement of their consumers.

Apple is very much strategically strong in case of material sourcing and development of the finish products. It has been seen that the company depending upon the conditions, sources its raw materials. The main source of the sourcing of the raw material is the local market and the rest of the material it sources from majorly Asian continents. According to Cool and Schendel (2010) the human assets what is required for the finishing the products the company majorly sources from Indian and China. The main parts what are required for the operational purpose apple majorly develop those parts within their plants. In California, they have developed a fully automated plant for making the main electrical instruments for the company. One of the market analyst stated that through implementing the in-house raw material development strategy apple remained able to standardize its product quality Mitchell et al. (2013).

ORDER This Operation Management Assignment NOW And Get Instant Discount

Apple gets the major advantage as their sources their base level raw materials from the local suppliers. They develop a long-term agreement with the local suppliers so that they remain able to receive a stable sourcing of the raw materials for their products. According to the study by Andersen and Minbaeva (2013), the company developed a loyal supplier base that enabled the company to receive the stable source of the raw materials and this has given them the advantage in the production line. One of the supplier told that the agreement what they have with the company enables them also to gain profit and ensures that they receives a stable cash inflow in their system.

Technology advancement: E-procurements

As opined by Shahzad (2008), Apple develops the formalised list of supply chain management for their suppliers and quickly moves towards developing the agreements exclusivity (Peng et al. 2009). Apple makes good relationship with their suppliers via E-procurement system that helps them to achieve the scale of operation for meet the demand of their consumers and generates higher profits. Using the supply chain management riot into make an impressive contribution that allows them for sustaining their business activities and gather various opportunities for future development in their local communities.

Supply chain (TQM)

The participant of economic activity committed their operation successfully and focuses on their supply chain management due to safety and prosperity of economic within Rio Tinto (Shafique, 2013). Within the business process of supply chain management, expertise of COFCO logistically improves their business and run successfully the business organisation. Applying for the dynamic role within their business process organisation achieve great success and achieve future opportunities. The supply chain management improves the quality and practices the solutions over their business process (Altarawmneh and Al-Kilani, 2010). Moreover, supply chain management allows the company in achieving of continuous improvements in business sectors. In major cases, it is identify that various technology is use in business for reducing the extra cost and providing attractive design over the products. Apple introduces the innovation strategy for Operation Management and using in their business process reaches the top of its business (Omolo et al. 2013).

As discussed by McCann and Aravamudhan (2013), with the help of R&D Apple is constantly coming up with technology, the firm in business concern properly develops their products and deliver it to customers (Andersen and Minbaeva, 2013). In most of cases it is identify that the company using the latest technology, appropriate strategy and supply chain management develops the business successfully and run smoothly along with minimize the competition. It increases profits for the organization in business sectors (Hoffman, 2013).

1.5 Future of Apple and COFCO

Apple is the third largest mobile maker and the second largest information technology company. The biggest competitor of Apple is Samsung. Samsung follows low cost strategy. In terms of market share, Samsung is ahead of Apple. Samsung imports its electronics cheap from China that is the cheapest among the whole world (Cool and Schendel, 2010). Apple is the most popular and most followed brand in the United States. The biggest problem of Apple is its autocracy. It uses its own operating system in its devices whereas other companies hire it from Android or any other platform. It increases its cost. Whenever, a model gets old it loses its popularity. To cut cost and to increase the customer interest Apple may follow the lean Operation Management strategy. It increases the efficiency by integrating people and processes with the technology.

As discussed by Mitchell et al. (2013), COFCO is the biggest food processing company of China. All Chinese companies follow low margin strategy. Therefore, they face problems in changing market scenario. They sometimes lack in technology application. In global scenario, some countries have food sufficiency, whereas the other countries do not have. Now world trade organisations try to collaborate between them to keep symmetry in the market. If technology is used in the processes, they may increase their market share by 10% (www.COFCO.com, 2014).

1.6 Global supply chain and logistics model

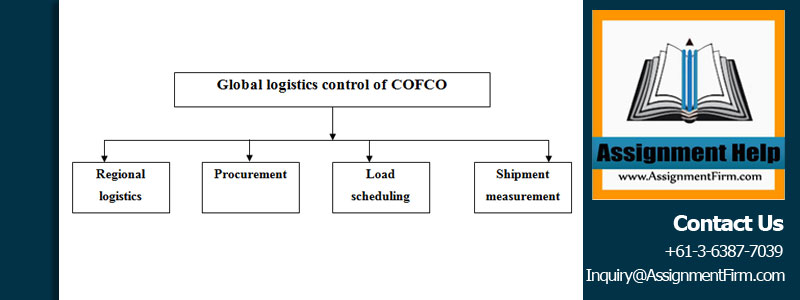

Figure 3: Global Supply Chain logistics of COFCO

(Source: Mitchell et al. 2013, p-195)

Global logistics chain of COFOC explains that company is having regional and exporting quality of materials from the manufacturing to the wholesaler. China oil and Food Corporation is one of huge supplier food items like grains, rice etc (Mura, 2012). One of the major missions of COFCO is to feed the general population worldwide. As per the global supply chain of the COFCO, suggest that com pay is able to create large customer base via global supply chain. COFCO uses E-Logistics method to supply in Asian and European market (Ebiringa, 2011).

Regional logistics: COFCO alone provides more than 94% of Chinese foods to the house hold in the regional geographic area. COFCO operates integrated value chain with diversified products in regional areas. Regional areas of chain are almost of 1.35 billion populations and more than 23 provinces that is one of the worlds 3rd larges after USA and UK (Ali, 2012). With E-logistics, process company tracts the record for the shipping, tracking and inter-communications between the business process manager and the commerce server.

ORDER This Operation Management Assignment NOW And Get Instant Discount

Procurements: By E-Procurement, company also had been able to track the record of procurement of raw materials like wheat, barley, malt and mustard flower for oil (Kaya et al. 2010). With E-procurement company makes the arrangement of collecting the inventory worth of 10% and 12% is always is present there.

Load scheduling: with increase in load scheduling COFCO has used to 3 major companies to reduce the freight forwarding and shipping agencies for port services. COFCO has in years uses various measure to control the load wastage but unable to reach to optimise it. COFCO is only able to manage only 11.09% of wastage control from the load scheduling because of poor time management (Koon et al. 2011).

Shipment: Since the company usually send its products within the data but COFCO fails to reach the products are right times because of the load scheduling problems. Shipment via port is also something that based on the geographical and weather report. Most of the times company fails to straddles it promise made in the contact (McCann and Aravamudhan, 2013). With E-logistics, company is able to operate in the most of the insight province of China like South and West province. As company is being exporting its products in the various country like Europe and US via aeroplane and other major shipment for which COFCO used E-Logistics method (Mitchell et al. 2013). COFCO uses various traditional and E-logistics for their B-to-B business support via wireless support track and trace which ultimate provides real time decision support.

| COFCO | Traditional | E-logistics |

| Shipment type | – | Parcel |

| Customer service | Rigid (within china) | Flexible (EU, US and UK) |

| Distribution model | Supply driven push (Within china) | Demand driven in EU and US |

| Inventory order flow | – | Bi-directional |

| Orders | Predictable (Within china Province) | Variables |

Apple global supply chain logistics:

Apple uses E-logistics advantage in supplying solution for the business (Shahzad, 2008). The ultimate objective of the Apple is to deliver the right products in the right quantities at the right place and at right time along with right customers.

By E-logistics company has integrated network and Improve the level of logistics, selecting right industries and building e-logistics product portfolio.

Integrated network system: Apple has another major network that helps the organisation to support the current Operation Management of the company. In order to support the E-logistics company manages to E-fulfilment represent the activities which is needed to ensure the customer gets what customer wants and when the customer wants (Wang et al. 2009). Most of the business of the Apple is related to the selling of phone for which great care and the perishable logistic is needed to maintain. Therefore company has uses E-fulfilment process in order to increased the large shipment base.

Via using STLC business model that is Slovenian transport logistics Cluster is another major logistics which chosen by Apple for their supplies in Europe and Asian market (Mitchell et al. 2013). STLC in association of more than 13 companies worldwide for port and ecological transportations. The STLC vision is to create large customer base for their products go beyond the traditional transportation system. Instead company uses STLC which Green and ecological in nature by consuming less fuel and complete control over the logistics (www.apple.com, 2014).

1.7 Global Manufacturing Strategy For Operation Management

Apple’s global manufacturing strategy is divided into two parts they develop the primary materials and the microprocessors in their own plant and they finish their products in China because of the low labour cost. According to Apple, they believe in the development of the quality products (Parnell, 2013). They have developed a fully automated plant in California and they are following the line production structure so that they remain able to reduce the ideal time and with the fully automated system, they remain able to reduce the wastage cost. Apple develops the semi-finished products in their US plants and their ships those materials majorly in China for the final assembly. This provides them with a dual advantage because the cost of assembling reduces and the distribution cost in the Asian market.

Apple disclosed that the development of the raw products through the automated plant in California has enabled them not only to increase their production but also helped them to maintain their product quality.

COFCO is the largest grain, oil and foodstuff and they mostly produce their products in by their own. In recent days the company has taken over other manufacturing company named Nidera, through doing this they made themselves able to produce the entire market requirement by their own. COFCO is very aggressively using the global network, developed by Nidera for the global distribution and trading purpose. According to a company source they are describing it as a win-win handshake for both the companies (Hoffman, 2013). This strategic alliance helped them to expand their arms in the global scenario. COFCO also develops a framework through its subsidiary companies for the global production and distribution.

Conclusion

Companies like Apple and COFCO are running their business for hundred or more years. They are well acquainted with their strengths and weaknesses. Still, they need to analyse the market at a regular interval because business scenario always changes in today’s competitive market. Apple can start using operating systems like android and windows, to increase the popularity in the market for Operation Management. It will help Apple to enter into new product segments. Apple does not have much market share outside the United States. Apple can join hands with other global leaders to increase their market value. COFCO uses different technologies to integrate the processes and the customer demand. It increases market share by selecting proper marketing mix as it is a food processing company.

ORDER This Operation Management Assignment NOW And Get Instant Discount

Therefore, it faces a lot of problem due to waste of its materials. It tries to minimize its waste by taking proper measures. It follows Six Sigma methodology to reduce waste. Cost reduction makes the products cheaper. COFCO follows E-Logistics and traditional for of logistics technique to cater the large customer base. Operation Management level of the Apple and COFCO are very different but both of the company uses TQM within their operations. Apart from that, the company is also been able to manage the large customer base via catering with SLTC and E-procurement techniques. Apple is very much using E-procurement and E-logistics for their products, which is to sell their products to in European, and Asian and African market. The company also uses STLC for ecological balance within the logistics.

Get GSB005 Managing Operational Improvement Assignment written by experts.